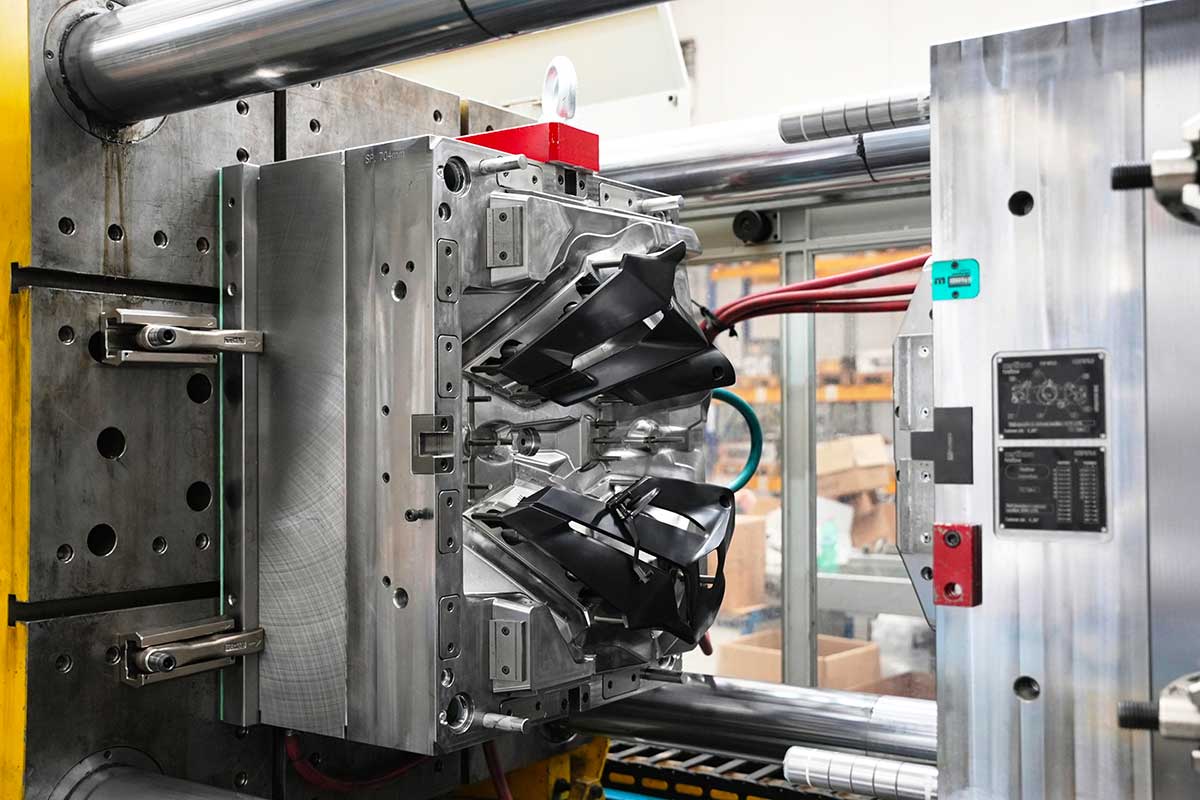

molds for plastic materials

FMB has over 35 years of experience in the design and manufacture of injection moulds for plastics. We offer customised solutions that meet our customers’ most demanding requirements and guarantee the highest standards of quality, precision and efficiency. We take care of every aspect: from the design of the plastic moulds to their production and complementary services.

molds for plastic injection

Organised departments, highly specialised personnel and a state-of-the-art machine park are the strengths that enable us to handle every order with the utmost timeliness, without neglecting any detail. FMB can take care of the entire process: from preliminary consultancy to the design of the plastic moulds, to the finished, packed, shipped product. Established partnerships with moulders and other suppliers in the supply chain also allow us to offer additional services, such as prototyping, test moulding, series moulding, and assembly of the final product. We offer a complete, punctual and efficient service. We accompany the customer at every stage by putting ourselves at his complete service, to shape ideas, solutions and visions.

molds for plastic materials

FMB has over 35 years of experience in the design and manufacture of injection moulds for plastics. We offer customised solutions that meet our customers’ most demanding requirements and guarantee the highest standards of quality, precision and efficiency. We take care of every aspect: from the design of the plastic moulds to their production and complementary services.

molds for plastic injection

Organised departments, highly specialised personnel and a state-of-the-art machine park are the strengths that enable us to handle every order with the utmost timeliness, without neglecting any detail. FMB can take care of the entire process: from preliminary consultancy to the design of the plastic moulds, to the finished, packed, shipped product. Established partnerships with moulders and other suppliers in the supply chain also allow us to offer additional services, such as prototyping, test moulding, series moulding, and assembly of the final product. We offer a complete, punctual and efficient service. We accompany the customer at every stage by putting ourselves at his complete service, to shape ideas, solutions and visions.

molds for plastic materials

The production of molds for plastic parts is the result of an accurate design phase. We develop customized solutions, starting from a blank sheet of paper or transforming ideas into reality. We can work on the drawing provided by the customer as well as in reverse engineering. Our technical department has 12 employees: we integrate CAD/CAM software for efficient design to make the subsequent production phases fast and accurate. The competence of our technicians and the constant dialogue with the customer allow us to quickly develop molds for plastic materials with high standards of efficiency and durability.

We provide precise, high-performance and complete solutions.

aluminium and steel mould

Our production department employs highly qualified personnel with solid experience in the manufacture of steel and aluminium moulds. Thanks to a large, diversified and fully automated machine park, we are able to meet every production requirement with great attention to detail. We create moulds of any size, always ensuring an excellent final product. Our dedication to innovation and updating allows us to produce advanced solutions and to support our customers with attention and punctuality.

molds for plastic

FMB is specialized in the design and production of injection molds for plastic materials for different sectors. The vast experience acquired, allows us to support customers by creating molds for the most diverse application areas including: